Roofing Sheet

Home » Roofing Sheet

Roofing Sheet

New Life profile sheet is made from the finest quality cold rolled steel coils which are coated with protected metallic and reinforced with multiple layers of organic coatings. New Life profile sheet can be readily roll-formed, bent, pressed, cut, drilled, lock-seamed and stamped to suit the specific requirement without degradation in the quality of the paint. We provide our clients with 3 D view of various color combinations that can be offered in the structures with good aesthetics .

Applications:

- Durability

- Affordability

- Environment Friendly

- Constructability

- Light weight

- Vibration Performance

Advantages:

Weather Proof & Strength

Long Life

Various Color Options

Economical

Maintenance Free

Easy to Install

Aesthetics

Relocatable

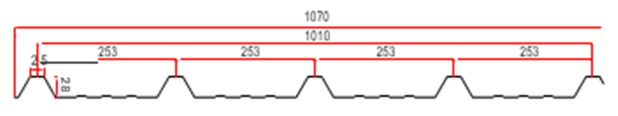

New Life Roof Profile Sheet :

Types of Materials Used:

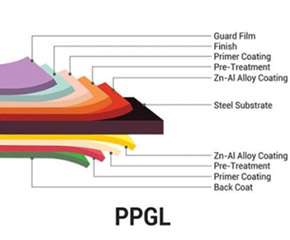

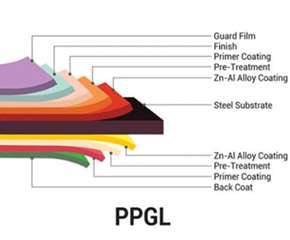

PPGI is also known as pre-painted galvanized steel, while PPGL is known as pre-painted galvalume steel. PPGI uses galvanized sheets with a layer of zinc coating as base metal. While PPGL is with galvalume sheet as substrate, which is coated with 55% aluminium, 43.3% zinc, and 1.6% silicon. Heat resistance of the PPGL sheet is much better than that of the PPGI sheet due to aluminium zinc content. PPGL sheets can withstand up to 315 °C, Hence they have better corrosion resistance than PPGI . Zinc coating and Aluminium Zinc Coating are used to protect metal from rusting to increase life of sheets but in case of PPGI ( zinc coating) base metal will be damaged once zinc coating is corroded . While aluminium Zinc coating last longer than PPGI as aluminium corrodes very slowly.

So, Al-Zn coating is more corrosion-resistant than zinc-coated steel sheet. According to data, the service life of PPGL is 3 times longer than that of PPGI. Due to the better performance and fewer qualified manufactures, the price of the PPGL sheet is 3%-11% higher than that of the PPGI sheet.

Geographically, PPGI is suitable for hot or cold places. While PPGL is suitable for rainy or coastal areas.

Storage & Handling:

One of the important factors while purchasing these roofing sheets is to ensure it is handled and stored in dry place for long Life. Storage places where water or condensation is possible may damage the coatings beyond repair. At construction sites the sheets should always be kept above ground using wood or rubber and covered always until the fitting in structures are not done.